PRESENTATION

- Our Model Potato Planters are designed for fast and professional planting of all potato seeds for large fields. We have 4 different models with spring-fixed feet and spraying system-without spraying.

- If the model with machine spraying system is preferred, it is also done automatically in seed spraying.

- There are 4 different plate options according to the seed size for perfect planting.

- The sewing process is done automatically without the help of workers.

- Planting distance on the row can be adjusted using the gears on the machine.

- The planter feet can be adjusted to suitable sowing depths and leaves the seeds at the same depth.

- Thanks to its spring feet, it does not compress the subsoil and prevent plant growth.

- The amount of seed planted in each row is the same.

- The seed lines created are equidistant to each other.

- Since the sewing process is more rapid, it saves time.

- End bars made of special steel and heat treated are resistant to abrasion.

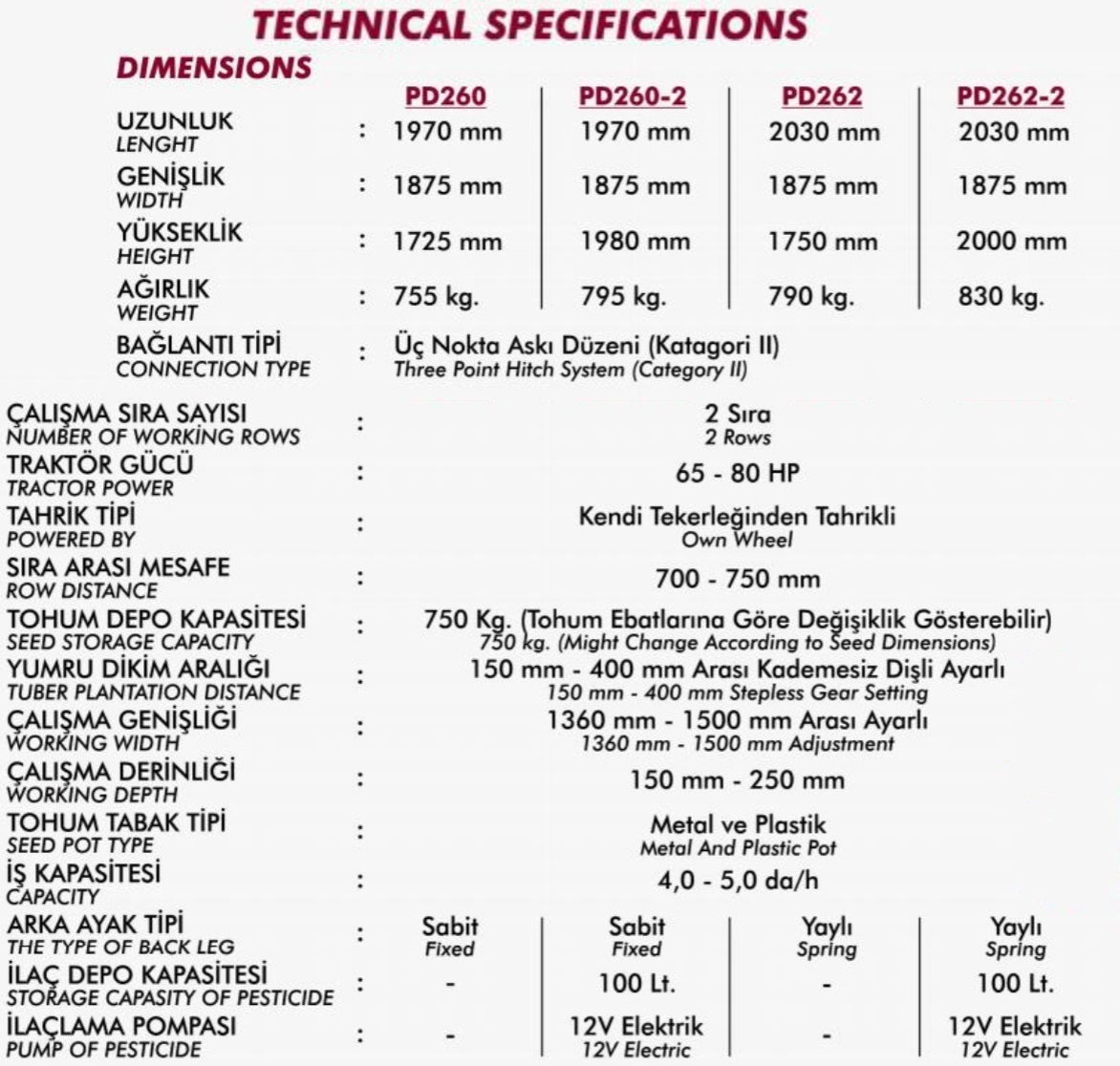

OVERALL DIMENSIONS PD260 PD260-2 PD262 PD262-2

Length: 1970 mm 1970 mm 2030 mm 2030 mm

Width: 1875 mm 1875 mm 1875 mm 1875 mm

Height: 1725 mm 1980 mm 1705 mm 1950 mm

Weight: 720 kg 760 kg 720 kg 720 kg

Connection Type: Three Point Suspension Arrangement (Category II)

TECHNICIAL SPECIFICATIONS

Number of Working Rows: 2 Rows

Tractor Power: 60 – 75 HP

Drive Type: Self-Wheel Driven

Seed Storage Capacity: 500 – 600 kg (May vary depending on seed size.)

Row Distance: 700 – 750 mm Adjustable

Tuber Planting Range: Between 150 mm – 400 mm, Stepless Gear Adjustable

End Iron Hardness: 46 – 50 HRC

Working Width: Adjustable Between 1360 mm – 1500 mm

Working Depth: 150 mm – 250 mm

Work Capacity: 5.0 – 6.0 hours

Seed Plate Type: Plastic Pit

Foot Type: Fixed Fixed Spring Loaded

Drug Storage Capacity: – 100 Lt. – 100 Lt.

Spraying Pump: – 12V Electricity – 12V Electricity

Number of Spraying Nozzles: – 4 Pieces – 4 Pieces

WORKING PRINCIPLE

The machine is connected to the tractor with a three-point hitch. Prepared seeds for planting are filled into the warehouse. Potato tubers in the warehouse are automatically taken into the plates from two compartments by a conveyor chain with two rows of metal hollow plates. The seeds are moved up by the rotation of the conveyor chain. The seeds that reach the plates in excess during transportation are dropped back to the storage. The seeds that are left alone in the plates are left to the bed opened by the planter foot. When our model with spraying system is preferred, it is done in seed spraying during planting. The planting process takes place by covering the left seeds with the help of eared furrow covering feet.

Ask and Receive your offer same day!!!